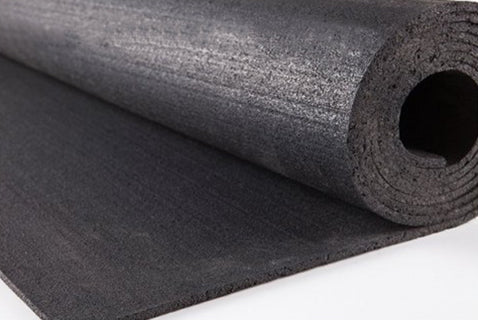

GenieMat RST is a revolutionary acoustic underlayment that offers high level sound reduction for multi-family dwellings, high-rises, and commercial structures.

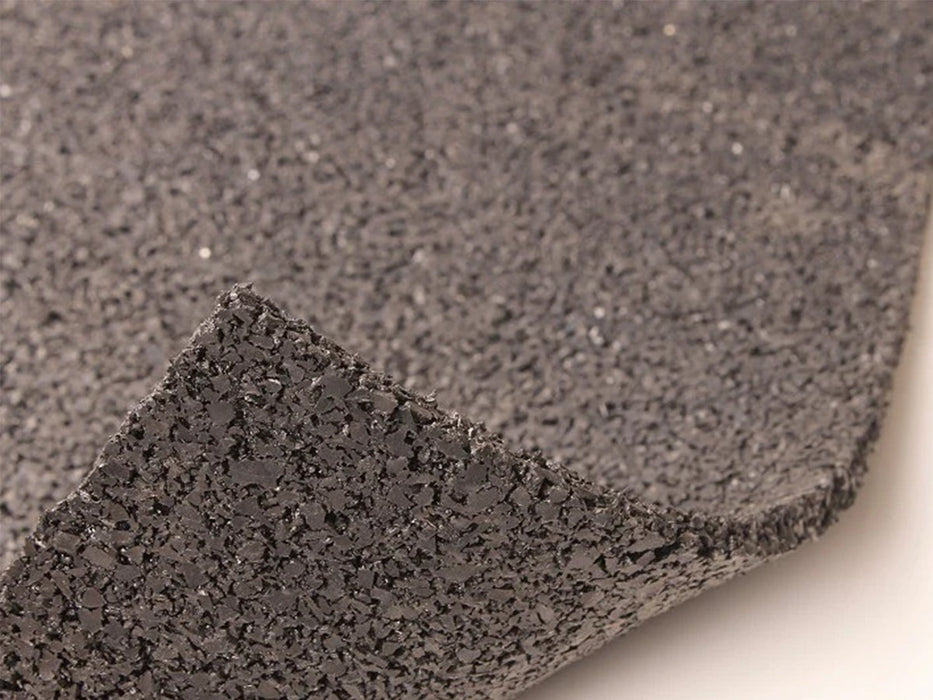

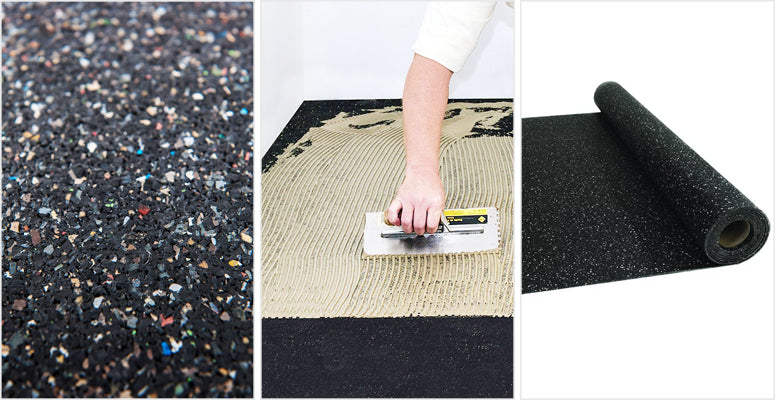

GenieMat RST is an eco-friendly and dependable option for hard floor surfaces in both concrete and wooden structures. This product, which is made from 94% recycled rubber, is suitable for covering tile, stone, wood, and vinyl floors, and it offers excellent protection against cracking of the base as well as enhanced sound insulation.

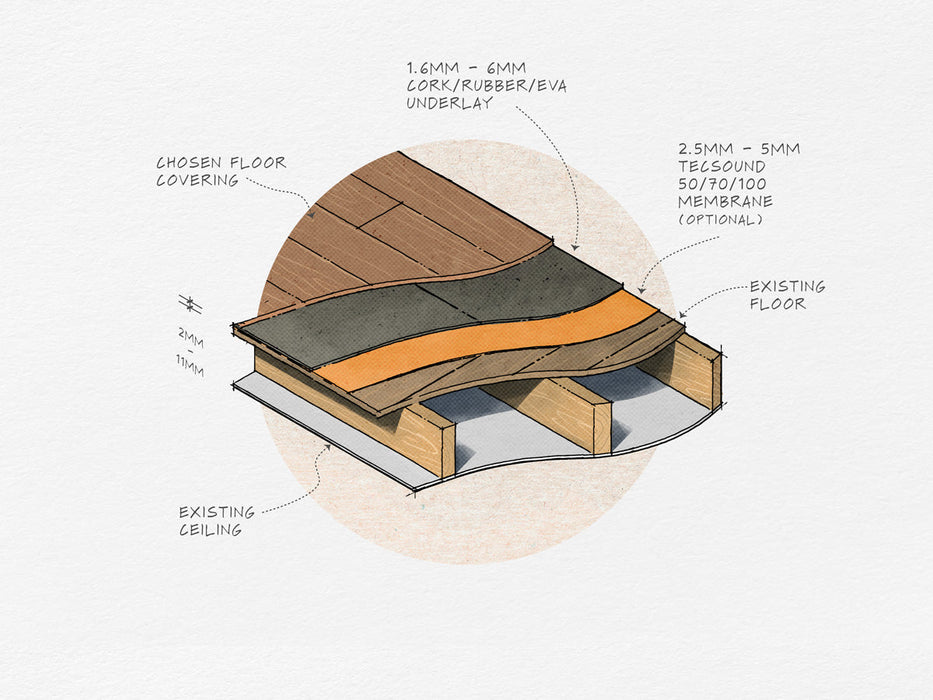

The GenieMat RST Underlay has proven to be a great choice for those looking to install laminate flooring while simultaneously dampening the noise that would otherwise be heard by neighbours below. It is an incredibly versatile mat that can be used to insulate a cement subfloor, effectively reducing the amount of impact sound that is produced. In addition to its great sound-proofing capabilities, the GenieMat RST Underlay is also an incredibly cost-effective option compared to other impact mats on the market.

Mats made from materials that effectively restrict moisture transfer are the ideal choice for any flooring application, as they provide superior protection from shock, impact and vibration, while also reducing the risk of mould and mildew growth and protecting your flooring.

Installation of Geniemat RST is simple and can be dry-laid onto floorboards or glued with GenieMat Adhesive, for more detailed instructions, check out the GenieMat RST Simple Installation Manual and GenieMat RST Technical Installation Manual.